About Us

Why are bearings always prone to damage at the same location?

Views : 7

Update time : 2025-10-13 13:45:25

Why are bearings always prone to damage at the same location?

"The number one headache": bearings keep breaking in the same location.

A bearing in a certain bearing housing on a critical piece of equipment on the production line would fail again after being replaced, less than a third of its expected lifespan. This cycle repeats itself over and over again.

What problems do we face with this symptom?

1. High hidden costs: Not only the cost of the bearing itself, but also the machinery downtime and labor costs associated with each replacement, as well as the unnecessary disruption to production plans.

2. Difficulty in Finding the Root Cause: In this case, we can generally conclude that the problem isn't with the bearing, but rather with something we can't see, such as a minor issue with the machine itself.

3. Mental Frustration: Who can handle having to buy something over and over again? The key is not being able to find the cause, which is the most frustrating thing.

So, do we have any good suggestions or solutions for this problem?

Of course we do. Based on our 30 years of experience in bearing production, I can responsibly assure you that following the following methods will solve at least 90% of your problems.

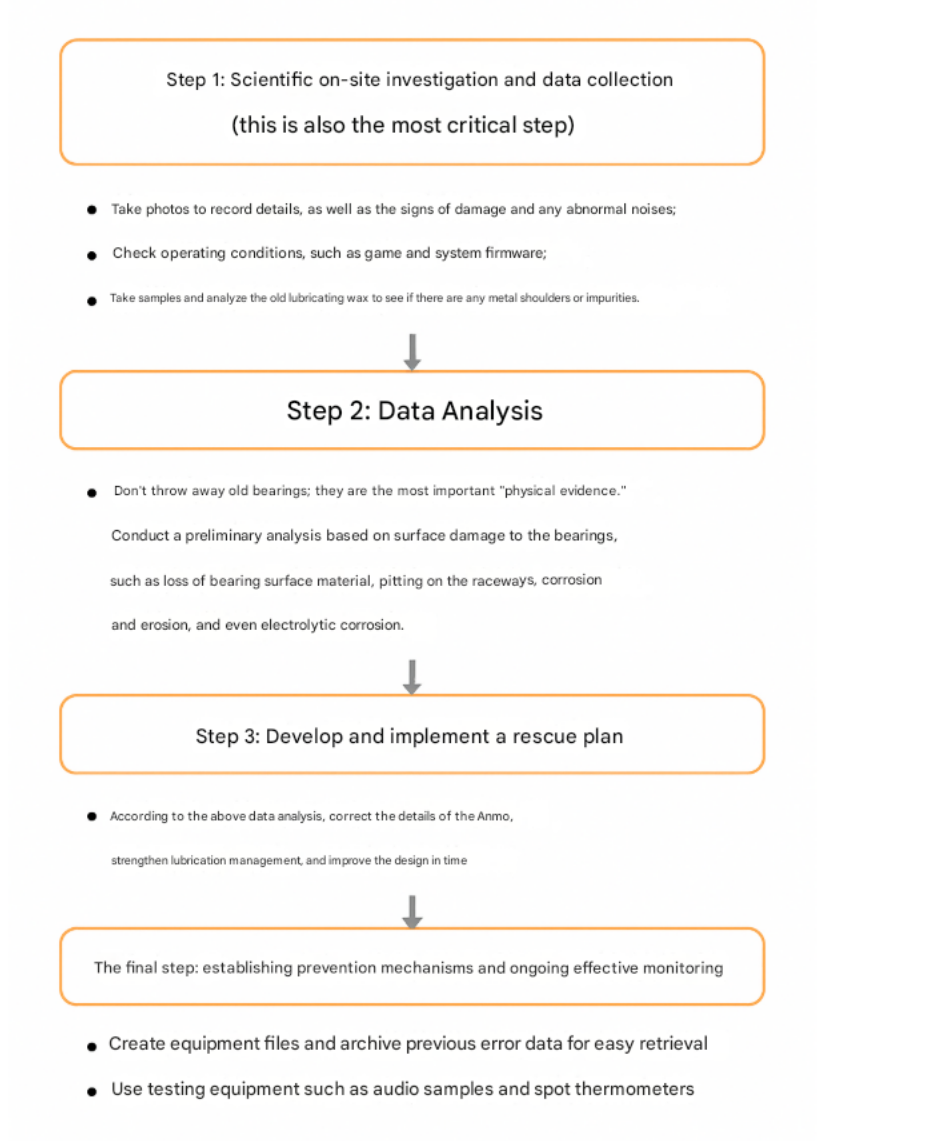

The first step is a scientific on-site investigation and data collection (this is also the most critical step): Take photos to record details, including the signs of damage and abnormal noise; check operating conditions, such as clearance and basic firmware; and take samples and analyze the old bearings. Check the grease for metal shavings and impurities.

Step 2: Data Analysis: Don't throw away old bearings; they are the most important "physical evidence." Conduct a preliminary analysis based on surface signs of bearing wear, such as loss of bearing surface material, pitting on the raceways, corrosion and rust, and even electrolytic corrosion.

Step 3: Develop and implement a repair plan. Based on the above data analysis, correct installation details, strengthen lubrication management, and make timely design improvements.

Step 4: Establish a preventive mechanism and continuous, effective monitoring. Create an equipment archive to archive previous error data for easy reference. Perform regular inspections using testing equipment such as stingers and thermometers.

We hope the above steps can effectively help you resolve your current challenging issue.

What other common or troublesome issues do you encounter?

We welcome your discussion.

相关新闻

Why are bearings always prone to damage at the same location?

Why are bearings always prone to damage at the same location?

Oct 13,2025

Why are bearings always prone to damage at the same location?

Bearings:The silent force that moves the world

Bearings:The silent force that moves the world

Sep 08,2025

Bearings:The silent force that moves the world

Bearing Industry in 2025: Finding New Growth Engines Amid Changes and Challenges

Bearing Industry in 2025: Finding New Growth Engines Amid Changes and Challenges

Aug 17,2025

Bearing Industry in 2025: Finding New Growth Engines Amid Changes and Challenges